Linear motion systems are an essential part of any machine or automation process, and they’re used in any number of industrial applications. To properly use them, it’s essential to understand what they are and what they do. They are mechanical devices that allow you to transfer energy from one point to another, much like a winch in reverse. But because of their type of energy transfer and how they work, linear motion systems can be broken down into different categories based on how the energy transfer occurs within them.

How Does A Linear Motion System Work, And How Do NRS Bearings Work?

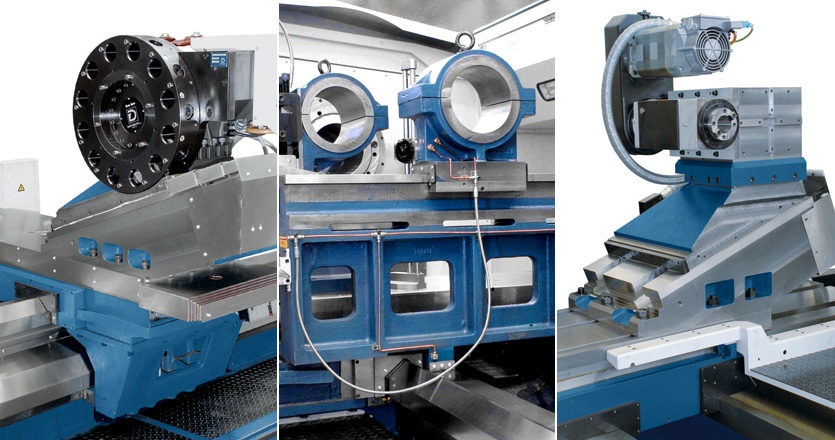

A linear motion system comprises two major components: a guiding rail and a powered carriage. The carriage attaches to the rail at one end and slides along its length with a degree of freedom at the other. The most common type of linear system uses an electric motor for power. When the power is applied in a direction perpendicular to the rails, it causes the carriage to move away from the motor’s location. In this instance, if you place an object on top of the carriage and apply pressure, it will slide in that direction as long as it maintains contact with both rails. If you used more force on one side than another, it would cause lateral movement because only one wheel would maintain contact with that particular rail.

NRS Bearings (ตลับลูกปืน LM Guide NRS, which is the term in Thai) are one of the simplest types of the linear motion system. They involve a bearing and some track. One end of the bearing is mounted to a motor or some other type of rotating shaft. The other end is mounted on a sliding object that moves along the track. When you turn on the motor, it spins, and this causes this object (the slider) to move along a single axis.

Tips For NRS Bearings Installation

Before you can install your bearings, you need to make sure that you have the right size of bearing for your axle. The inner diameter of a 5/16 bearing is 0.313. The outer diameter of a 7/16 bearing is 0.465. These two diameters’ differences may seem small, but it is crucial when installing bearings onto an axle. After this, take your wheel and hold it up next to the appropriately sized bearing, then Place the new bearing into the hole on top of your wheel and push it down. Finally, install your cotter pin or lock nut.

The 3 Parts Of A Linear Motion System

A linear motion system is a set of components that work together to produce linear movement. Linear motion systems are used in various machines and consist of three main parts. The first part is the actuator (motor) which turns rotational energy into linear momentum. The second part is an axis that connects the actuator and load. And lastly, there is a carriage where the cargo moves along.